QUALITY CONTROL IN RADIATION PROCESSING IN THE VINČA INSTITUTE RADIATION PLANT- CASE STUDY

Abstract

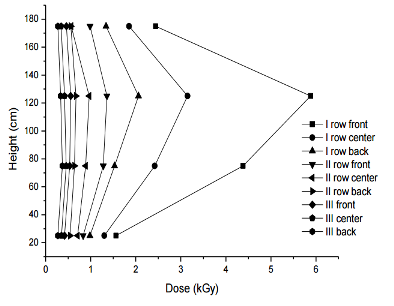

The irradiation process control has to define facility parameters, validation of product and routine control of the irradiation process during exploitation. To meet the regulations, it is necessary to stop the exploitation and do the qualification exercises after changes in the source loading, source geometry or product transport system. In order to save time, the new combined approach has been analyzed for qualification of sterilization process used in the Vinča Institute Radiation Plant. The absorbed dose is calculated assuming that the irradiation process runs with specified parameters. The results of absorbed dose measurements in an experiment done during the sterilization process were used for dose calculations. The calculated absorbed doses are compared with measured ones. The criterion for a positive qualification is the superposition of calculated and measured values. Two different types of dosimeters are used for measurements: ethanolchlorobenzene and alanine. The measurement traceability is achieved through the calibration by the Riso National Laboratory, Denmark. In this case study, the determined dwell time for target dose is 450s. 1.23 is dose uniformity ratio in the box with plastic products with dose minimum at the bottom corners in the center and dose maximum at the top of the surface plane of the box parallel to the source. The calculated and measured absorbed doses show the same difference of 13% between the surface and the central plane in the box. The dose reproducibility for irradiation process is 3.5%.

Keywords

Full Text:

PDFReferences

ISO/ASTM 51026-15 Standard practice for using the Fricke dosimetry system

ISO/ASTM 51261-13. Standard practice for calibration on routine dosimetry systems for radiation processing

ISO/ASTM 51538-09. Standard practice for use of the ethanol-cholrobenzene dosimetry system

ISO/ASTM 51702-13. Standard practice for dosimetry in gamma irradiation facility for radiation processing

ISO 11137 2006. Sterilization of health care product – Radiation: Part 1: Requirements for development, validation and routine control of a sterilization process for medical devices. ISO 11137-1, 2006, Geneva. Part 2: Establishing the sterilization dose. ISO 11137-2, 2006, Geneva. Part 3: Guidance on dosimetric aspects. ISO 11137-2, 2006, Geneva

Marković V. M., Eymery R., and Yuan H. C.,1977. A new approach to 60Co plant design for introduction of radiation sterilization in developing countries. Radiat. Phys.Chem.9, pp. 625-631

Radak B. B., Marković V. M. and McLaughlin W. L., 1979. Dosimetry for the commissioning of a versatile irradiation plant. Radiat. Phys.Chem. 14, pp. 449-456

Šećerov B. and Bačić G., 2011. Calibration of routine dosimeters in radiation processing: validation procedure for inplant calibration. Nuclear Technology & Radiation Protection 26, pp. 271-274

Šećerov B., Radenković M., Dramićanin M., 2016. Uncertainty and routine use of Aerial L-alanine - Electron spin resonance dosimetry system. Radiation Measurements (2016). http: //dx.doi.org/ 10.1016/j.radmeas.2016.03.003

Sharpe P. and Miller A., 2009. Guidelines for calibration of routine dosimetry systems for use in radiation processing. NPL Report CIRM 29, available at http://www.chemdos.npl.co.uk/dosc/NPLReportsCIRM29.pdf

Refbacks

- There are currently no refbacks.

ISSN 0354-4656 (print)

ISSN 2406-0879 (online)